CNC Machining Materials

Explore metals, plastics, and engineered polymers machined with precision for high-performance parts and repeatable results.

Find the Right CNC Machining Material for Your Next Project

Your job is to choose CNC machining materials that will make your part perform under load, in motion, and in real-world conditions. The material has to be right, the tolerances have to hold, and the part has to work the first time.

Ephrata Precision helps you evaluate your CNC material list and shows you how each option behaves in machining and in the field. You get clear guidance, practical insight, and a material choice you can trust.

Metals

Complete CNC Materials List

Aluminum

Lightweight, strong, and easy to machine. Excellent for housings, brackets, and parts that need tight tolerances without added weight. Reliable for CNC milling and turning with clean finishes and predictable performance.

Machines cleanly with great finishes and minimal tool wear. Ideal for fittings, valves, connectors, and components needing corrosion resistance or conductivity. A stable, low-friction material for CNC turning.

Built for motion-heavy parts like bushings, bearings, and wear components. Offers low friction and strong durability under load, making it ideal for sliding or rotating applications.

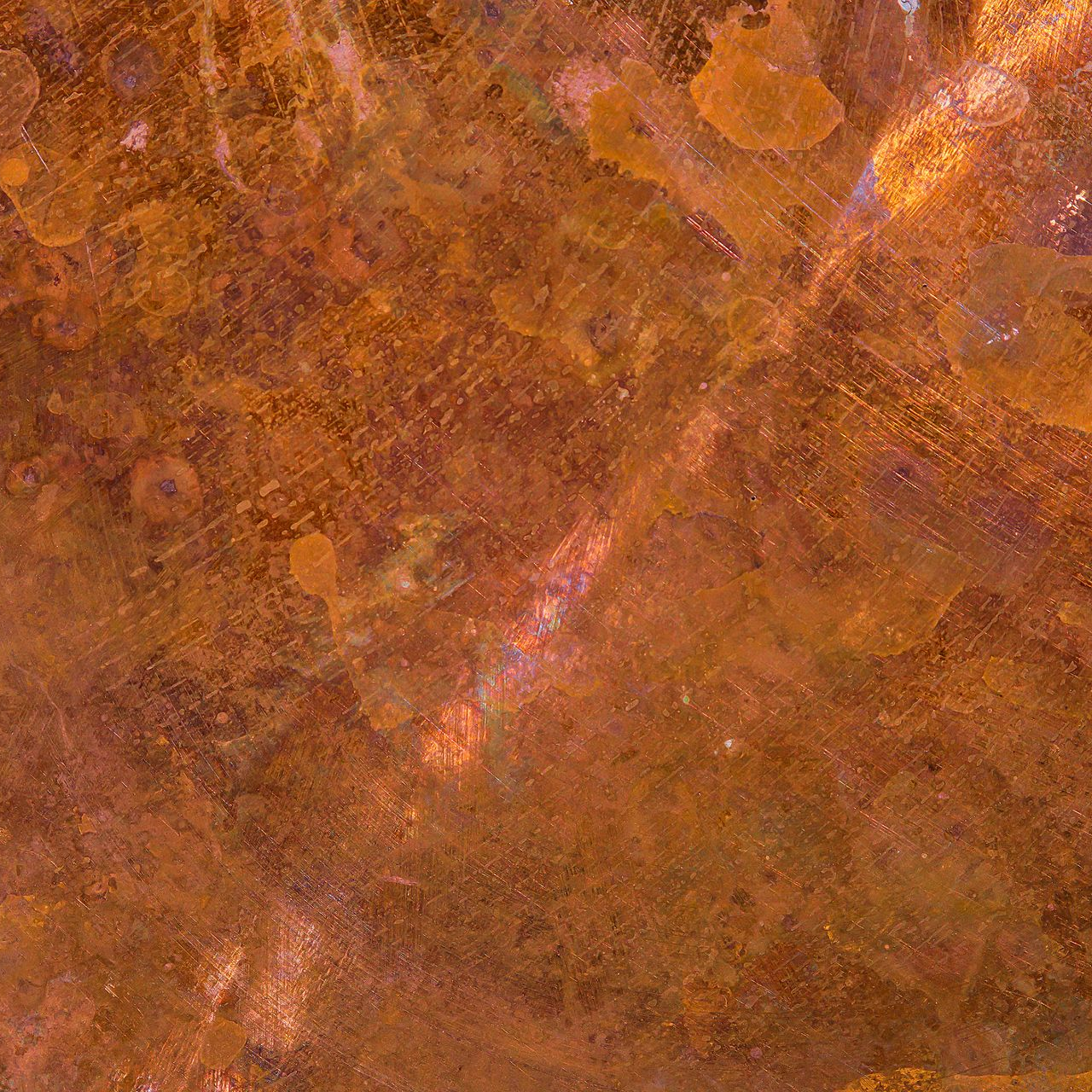

Copper

Exceptional electrical and thermal conductivity. Common in contacts, heat sinks, and specialized components. Softer to machine but delivers reliable performance where conductivity matters most.

Stainless Steel

Strong, corrosion-resistant, and long-lasting. Used in medical, food-processing, chemical, and high-load components. Tougher to machine but produces highly durable, stable parts.

Carbon Steel

Strong, affordable, and dependable. Excellent for structural components, shafts, and fixtures requiring toughness. Machines are predictable and offer high mechanical performance.

Alloy Steel

Enhanced strength, hardness, and heat resistance. Ideal for gears, tooling, and components under heavy stress. A good balance of durability and machinability.

Tool Steel

Engineered for extreme wear and impact. Used for dies, molds, punches, and heavy-duty tooling. Challenging to machine but delivers exceptional hardness and longevity.

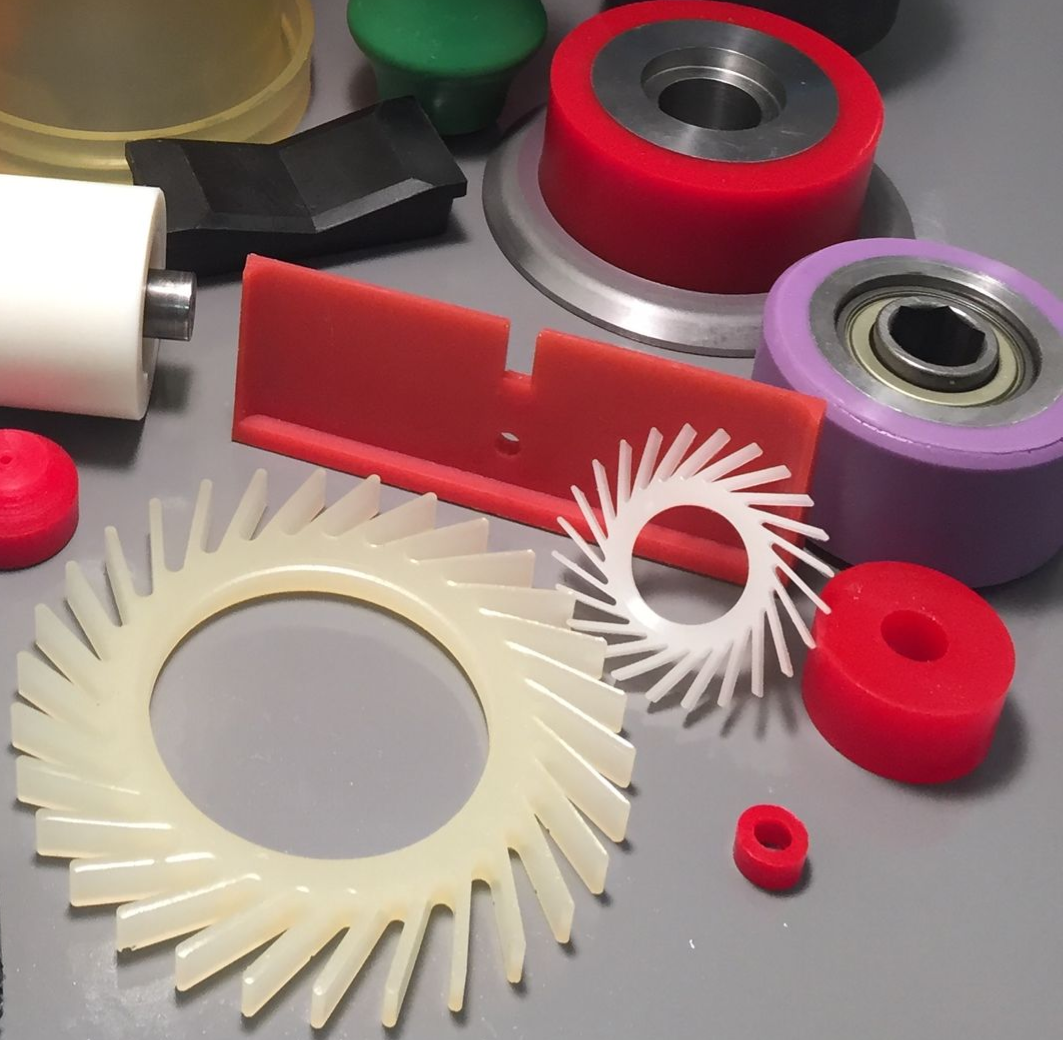

Plastics & Engineered Polymers

Complete CNC Materials List

Delrin / Acetal

Strong, low-friction, and dimensionally stable. Great for gears, bushings, and rollers. Machines clean and hold tight tolerances.

Nylon

Tough, flexible, and naturally wear-resistant. Ideal for spacers, bushings, guides, and components needing impact strength without brittleness.

Nylatron GS

Nylon is enhanced for lower friction and better wear. Excellent for sliders, bearings, and high-load, high-speed applications.

Polycarbonate

Impact-resistant and lightweight. Common for guards, covers, and housings requiring clarity or toughness. Machines clean with the right tooling.

UHMW

Extremely abrasion-resistant with very low friction. Perfect for wear strips, guides, liners, and sliding components.

Polyurethane

Flexible, shock-absorbing, and durable. Used for rollers, bumpers, seals, and parts that need impact resistance or vibration control.

Teflon (PTFE)

Chemically resistant, low-friction, and stable at high temperatures. Ideal for seals, insulators, and components in harsh environments.

What Makes a Good CNC Machining Material?

The right material must support the part's intended use. When evaluating CNC machining materials, these qualities influence tolerance, stress management, and long-term performance.

Machinability

How cleanly the material cuts, how stable it stays during machining, and how reliably it hits the tolerances your design requires.

Strength and durability

The ability to handle load, impact, force, or long-term stress without deforming or failing.

Wear/friction performance

Crucial for bushings, guides, and moving components. Materials must resist abrasion, galling, and surface breakdown.

Thermal stability

Parts exposed to heat or continuous motion must stay dimensionally accurate and resist warping or creep.

Chemical/environmental resistance

Important for food, medical, chemical, outdoor, or moisture-heavy environments where corrosion or degradation can shorten part life.

How to Select the Right CNC Material for Your Application

These quick comparisons make it easier to choose CNC machining materials based on strength, precision, wear performance, weight, or cost.

What CNC materials are best for high-strength parts?

Stainless steel, alloy steel, carbon steel, and tool steel are the strongest CNC machining materials. They’re used when parts must handle load, impact, heat, or structural stress.

Which CNC materials hold the tightest tolerances?

Aluminum, brass, stainless steel, and Delrin hold tight tolerances because they stay stable during machining and resist warping. They’re ideal for precision CNC milling and CNC turning.

What CNC materials reduce friction or wear?

Bronze, Nylatron GS, UHMW, Delrin, and PTFE are common low-friction CNC materials. They perform well in sliding, rotating, and high-cycle applications.

When should plastic replace metal in CNC machining?

Use plastics when you need lower weight, corrosion resistance, chemical resistance, impact absorption, or electrical insulation. Delrin, nylon, and polycarbonate often outperform metals in moisture, motion, or impact-heavy environments.

What CNC materials offer the best cost-performance balance?

Aluminum, carbon steel, Delrin, and nylon offer strong performance at a lower cost. These materials machine quickly, hold tolerances well, and support efficient production.

Why Engineers and Manufacturers Trust Ephrata Precision

For over 50 years, Ephrata Precision has helped manufacturers machine parts that work the first time. Our 56,000 sq. ft. facility includes CNC machining centers, lathes, EDM, grinders, polyurethane equipment, and full inspection—giving you confidence that we can handle your material, your tolerances, and your production needs.

We’re known for reliability, communication, and consistent results. Every part is inspected, every order is supported, and every customer gets a machining partner they can count on.

What You Get

- 50+ years of machining experience

- Full CNC, EDM, grinding, and inspection capabilities

- Proven repeatability with CMM verification

- Support for Kanban and blanket orders

- Trusted by OEMs across multiple industries